Disposable foam food lunch box machine ( thermocal box machine|ps foam food container machine) designed by our company is all-powerful. The main way is vacuum forming as well as press forming and synthetical forming. It can be used for forming kinds of plastic sheets(learn about ps foam sheet making machine). This machine adopts PLC control, it has a group that possesses reliable stability, a large forming area, high production, and automatic degree.

Disposable foam food lunch box machine ( thermocal box machine|ps foam food container machine) designed by our company is all-powerful. The main way is vacuum forming as well as press forming and synthetical forming. It can be used for forming kinds of plastic sheets(learn about ps foam sheet making machine). This machine adopts PLC control, it has a group that possesses reliable stability, a large forming area, high production, and automatic degree.

The complete ps foam production line includes a PS sheet extruder, foam box forming machine (also named forming and cutting machine), and recycling machine. the foam box forming machine is one of the most important pieces of equipment.

- The PS sheet extruder melts PS pellets at high temperatures to extrude and cool them into foamed sheets (PS foam rolls), which serve as the raw material for foam products.

- The foam forming machine, showcased prominently on this page, shapes foam products into different varieties using molds of various shapes.

- The recycling machine reuses the scrap material generated during the production process, significantly reducing production costs.

PS foam food container machine can mainly form the PSP material products which are used to produce food containers, trays, bowls, cups, etc. Forming, cutting, and stacking is done in the same machine, saving labor, improving efficiency, lowing labor intensity, and reducing production cost. The production process is to put foam sheets into forming machines, and product and wastage will come out from the rear part.

Parameter For PS Foam Food Container Machine

| Model | Unit | DY-1040 | DY-1380 |

| Max.forming area | mm | 1000*1100 | 1100*1380 |

| Max.forming depth | mm | 80 | 100 |

| Capacity | s/mould | 3-5 | 3-5 |

| Forming pressure | T | 15 | 15 |

| Heating Power | Kw | 108 | 142 |

| Total Power | Kw | 168 | 204 |

| Total Weight | T | 15 | 16 |

| Overall size | m | 12*2*2.8 | 15*3.6*2.58 |

Features For Foam Food Container Machine

- The foam plate machine integrates vacuum forming, cutting, and stacking, offering versatile thermal forming capabilities.

- The foam plate machine production line produces a wide range of products including PS foam food boxes, disposable plates, take-away containers, egg trays, hamburger boxes, bowls, fruit trays, absorbent trays, and ceiling panels. It’s commonly used for packaging heat and frozen foods in supermarkets and stores.

- The take-away food container making machine features remote infrared ceramic heaters and heating pipes in the heating zone, ensuring stable temperature control.

- The PS foam machine is equipped with a temperature digital system, enabling workers to quickly monitor the temperature of each heating zone.

- The PS foam plate plastic dishes machine is controlled by a PLC controller and touch screen interface, allowing for easy operation. The PLC can store information for more than 10 molds, eliminating the need to reset data when changing molds

Detail Description

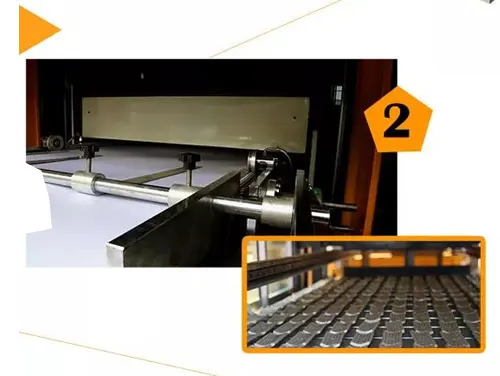

| 1. Foam Rolls Loader The feeding of the PSP sheet is automatically driven by a cylinder in the informed PSP placing unit.A rubber-covered roller is utilized to unroll the sheet,while photoelectric control ensures that two sheetsare put on each set of rollers simultaneously for efficient cycling use.  | 2. Heating Unit Intelligent temperature controller, meet requires of different temperature control in each heating zone. Heating box can be moved back and forth Heating box full use of asbestos packing  |

| 3. Vacuum Forming Unit The forming area measures 1100mmx1380mm, with a forming pressure of 20t and a maximum forming depth of 80mm.  | 4.Hydraulic Cutting Unit Max. cutting pressure: 120t Cutting type: hydraulic cutting system Cutting oil pump motor: 11KW  |

| 5. Automatic Stacking Unit stacking system: controlled by PLC, auto stacking, autocounting, auto removing Collecting products table board: 2 pcs (conveyed by belt) The products collection part adopts one 2.2KW motor to drive the ball screw to graduallydescend, and the photoelectric switch controls the up and down stroke to save the conveying time.  | 6. Online Recycling Unit The online recycling unit is characterized by efficient energy-saving capabilities, high productivity, fine particle crushing, and a small layout size  |

PS foam food container machine is used to produce food containers, trays, bowls, cups, etc. if you are interested in disposable foam lunch box machine, contact us now.

PS foam food container machine is used to produce food containers, trays, bowls, cups, etc. if you are interested in disposable foam lunch box machine, contact us now.