Fast food box machine (paper food container making machine) is specialized forming equipment designed for producing various paper products. It is capable of manufacturing cartons made of cardboard and corrugated paper, including hamburger boxes, square boxes, and food boxes (suitable for take-out).

Paper lunch box making machine features:

- Paper lunch box making machine boasts stable quality, high efficiency, with the highest speed reaching 160 PCS/MIN.

- Versatility: With the same machine, various products of different specifications such as lunch boxes, three-dimensional boxes, hamburger boxes, French fries boxes, and others can be manufactured simply by changing the mold

- paper food container making machine utilizes a water-based glue gluing device, ensuring high efficiency and precision

- Water-based glue is a food-grade adhesive that is water-soluble and highly safe.

The process of disposable paper lunch box making machine

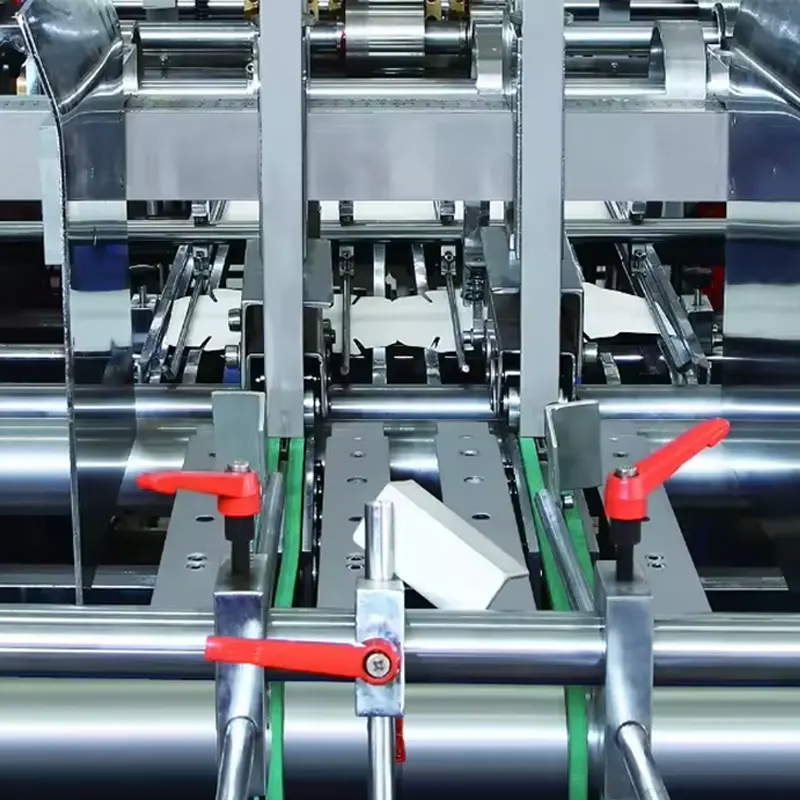

The feeder transports pre-printed and pre-cut cardboard from the paper shelf to the conveyor chains, guiding it to the shaping mold. During this process, the cardboard is glued, and you have the flexibility to adjust the gluing position. The amount of glue applied can be measured continuously without interrupting the operation. Once glued, the cardboard is conveyed for shaping and collection. disposable paper lunch box making machine automatically calculates the predetermined quantity and marks it without halting production.

The feeder transports pre-printed and pre-cut cardboard from the paper shelf to the conveyor chains, guiding it to the shaping mold. During this process, the cardboard is glued, and you have the flexibility to adjust the gluing position. The amount of glue applied can be measured continuously without interrupting the operation. Once glued, the cardboard is conveyed for shaping and collection. disposable paper lunch box making machine automatically calculates the predetermined quantity and marks it without halting production.

The parameters of lunch box making machine

| Raw Material | 200-600g/m² cardboard |

| Productivity | 60-200pcs/min |

| Box Length | 100-450mm |

| Box Width | 100-600mm |

| Box Height | 15-200mm |

| Power Source | 380V 50Hz |

| Total Power | 5.5Kw |

| Dimentions | 3600x1350x1500mm |

| Weight | 1800kg |

Detailed Introduction

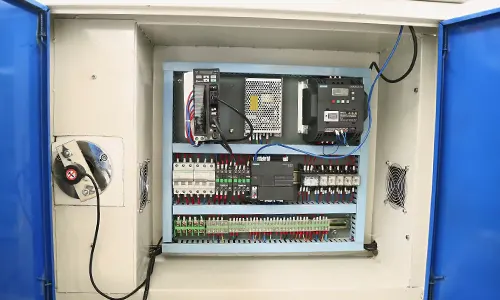

1. utilize internationally renowned brands for our electrical components, including Omron from Japan, Schneider from France, Siemens from Germany, and Delta, among others, for imported parts. 1. utilize internationally renowned brands for our electrical components, including Omron from Japan, Schneider from France, Siemens from Germany, and Delta, among others, for imported parts.Our systems are equipped with PLC programmable control and feature user-friendly touch screen interfaces. |

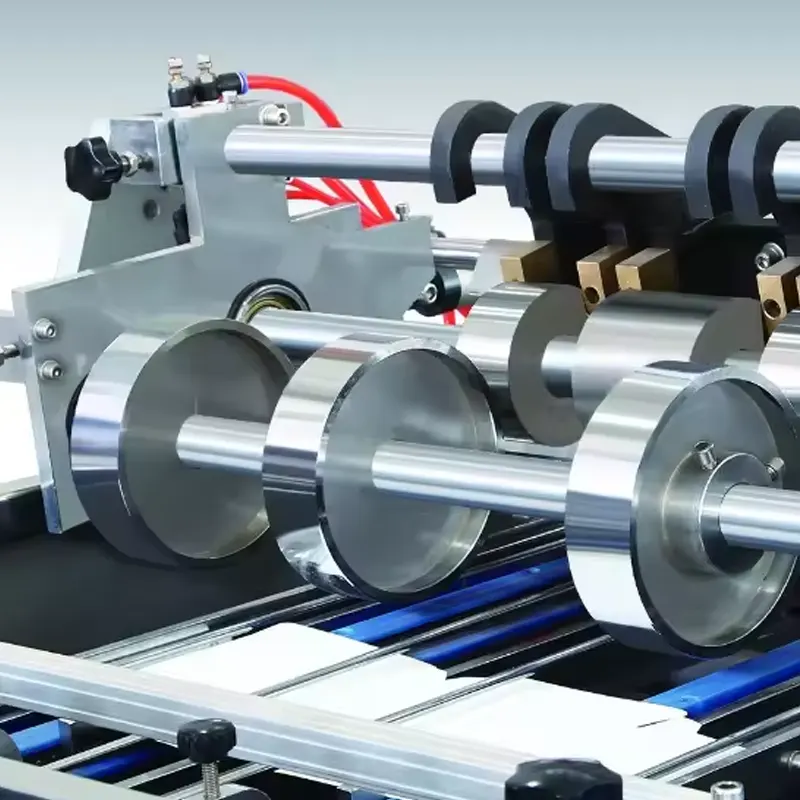

2. efficiently and precisely feeds water-based adhesive, ensuring precise application to the carton’s sealing edge. Its adjustable design allows for customizable glue dispensing. The device boasts a rational and compact design, ensuring stable operation while remaining easy to clean and maintain for utmost convenience. 2. efficiently and precisely feeds water-based adhesive, ensuring precise application to the carton’s sealing edge. Its adjustable design allows for customizable glue dispensing. The device boasts a rational and compact design, ensuring stable operation while remaining easy to clean and maintain for utmost convenience. |

3. fully automatic carton outing device encompasses feeding, collection, stacking, and counting functionalities. It is designed for seamless integration into the packing process, eliminating the need for manual labor. This system ensures efficient carton handling while streamlining the packing process, ultimately saving time and resources. 3. fully automatic carton outing device encompasses feeding, collection, stacking, and counting functionalities. It is designed for seamless integration into the packing process, eliminating the need for manual labor. This system ensures efficient carton handling while streamlining the packing process, ultimately saving time and resources. |

4. incorporates a photoelectric failure-detecting system, which automatically halts operation if it detects a lack of paper or any paper feeding blockages. This feature enhances safety performance by preventing potential hazards and reducing the consumption of resources, thereby optimizing cost-effectiveness. 4. incorporates a photoelectric failure-detecting system, which automatically halts operation if it detects a lack of paper or any paper feeding blockages. This feature enhances safety performance by preventing potential hazards and reducing the consumption of resources, thereby optimizing cost-effectiveness. |