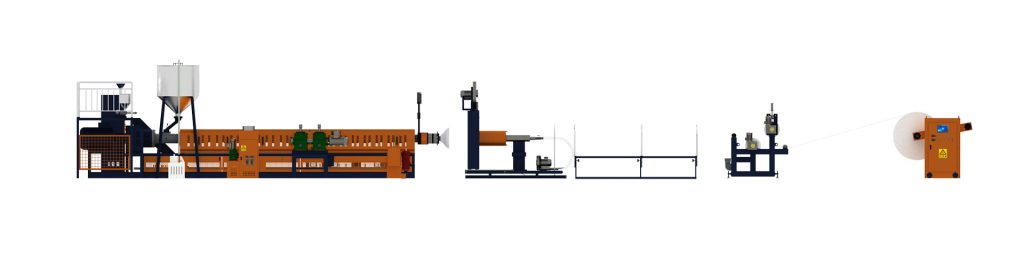

EPE Foam Sheet Extrusion Machine | EPE Foam Sheet Making Machine

An EPE foam sheet extrusion machine, also known as EPE foam machinery, is designed to produce EPE foam sheets with customizable widths and thicknesses based on customer requirements. This versatile EPE foam sheet machine can also manufacture other foam products, such as foam pipes, nets, rods, and foam profiles, by simply changing the mold and necessary parts. Ideal for various packaging and insulation applications, this machine offers flexible and efficient production solutions.

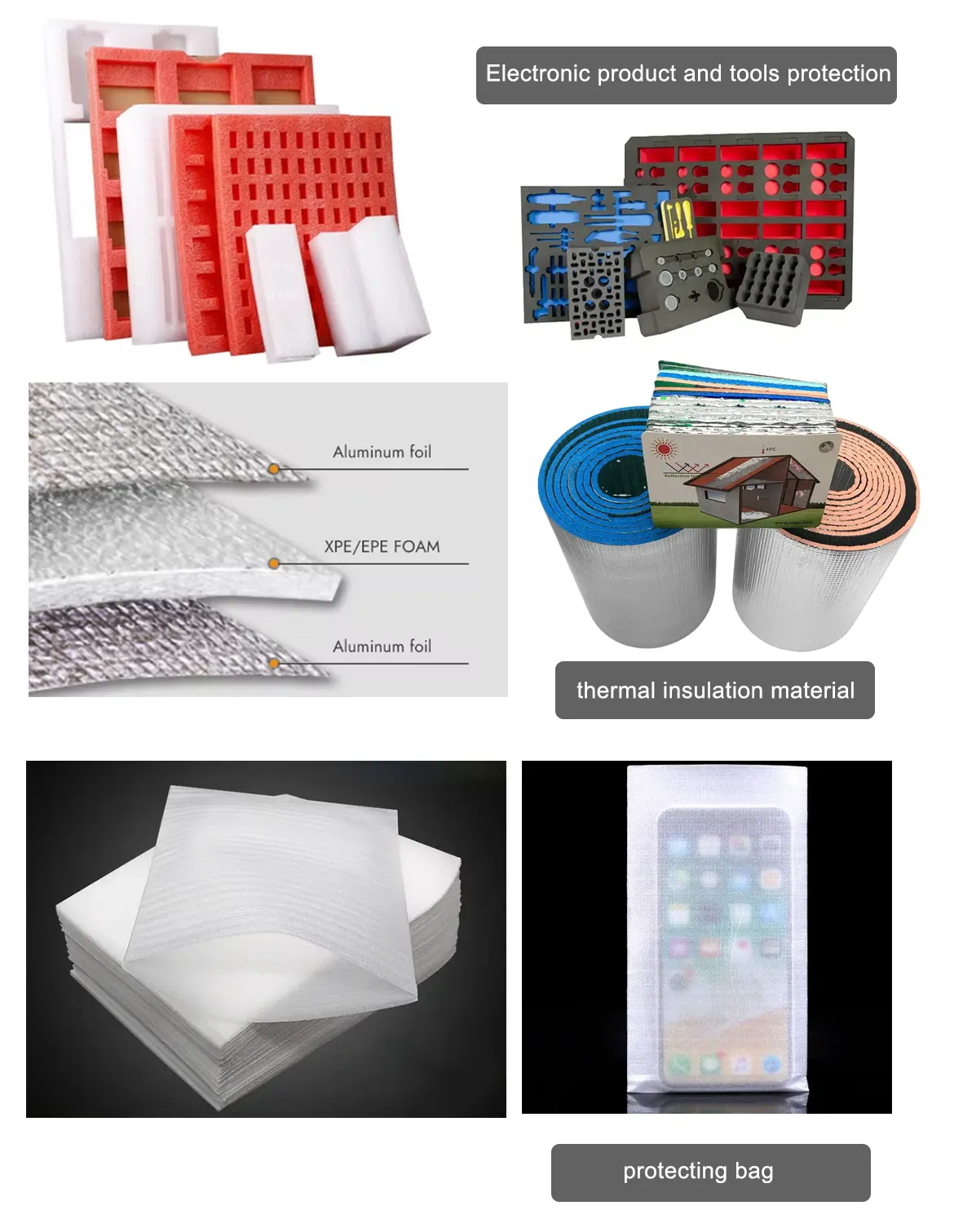

The foam sheet produced by the EPE foam extruder is dampproof, shockproof, soundproof, heat-insulating, and highly moldable. After laminating, it offers enhanced dampproof performance. These sheets are commonly used as underfloor insulation.

How to make epe foam sheets(polythene foam sheets)?

1.Material Preparation: The process begins with PE resin (polyethylene) as the raw material. Blowing agents, additives, and colorants may also be mixed in.

2.Extrusion: The prepared mixture is fed into the EPE foam extrusion machine.

Inside the machine, the mixture is heated and melted. A blowing agent is injected to create bubbles in the material, expanding it into foam.

3.Shaping: The molten foam is pushed through a die in the machine to form a sheet. By changing the die or adjusting the settings, different sheet widths and thicknesses can be produced.

4.Cooling: As the foam exits the machine, it cools down to solidify into the desired shape and thickness. It may pass through rollers to ensure uniformity.

5.Winding: Once cooled, the foam sheet is wound onto large rolls for easy handling and transportation.

6.Optional Laminating or thickening: For additional strength and dampproof properties, the sheets can be laminated with film, foil, or other materials. To protect electronic instruments or tools during transportation, EPE foam sheets are often thickened into boards and shaped into specific protective liners.

EPE foam sheet machine features:

- PE foam and related products are made from PE resin and it is expanded and formed into shapes by being heated and extruded. And it is easy to be decompounded and environment friendly.

- Its key function is cushion protecting and warmth reserving.

- Nowadays it is the most popularly used for modern batch production products, especially the export packaging industry, including electronic industry (such as PC computer, laptop, electronic chips, and parts, inverter, TV, air conditioner, refrigerator), furniture, glassware, garments, metal parts, etc.

- Whoever aims at modern packaging and export, has to use PE foam for the following reasons: Packaging with air bubble film, EPS, and plastic film is forbidden in many countries. Paper packaging is so expensive.

- PE foam products have quite a few varieties: Sheets for direct wrapping and to make bags; PE sheets may be coated with plastic film, craft paper

How many types of EPE Foam Sheet Extrusion Machines?

Model | Unit | DYEPE90 | DYEPE105 | DYEPE120 | DYEPE150 | DYEPE170 |

Screw diameter L/D | 90/55:1 | 105/55:1 | 120/55:1 | 150/55:1 | 170/55:1 | |

Screw speed | r/min | 5-45 | ||||

Foam rate | 20-40 | |||||

Width of product | mm | 1000-1400 | 1000-1500 | 1000-2000 | 1000-2000 | 1000-2000 |

Thickness of product | mm | 0.5-4.5 | 0.5-6.5 | 0.8-8 | 1-12 | 2-16 |

Cooling method | cooled by water | |||||

Installed capacity | kw | 110 | 130 | 170 | 240 | 285 |

Dimensions(L×W×H)(approx) | m | 22×2.3×2.2 | 23×2.3×2.2 | 25×2.3×2.2 | 30×2.3×2.2 | 32×2.3×2.2 |

Total weight(approx) | t | 8.5 | 9 | 12 | 15 | 17 |

Get Quotation Now: