Sugarcane bagasse food container making machine introduction

Sugarcane Bagasse Food Container Making Machineis a special equipment that uses special molds to control vacuum suction, dehydration and other actions through time to make pulp fibers into wet semi-finished products of paper mold products. The wet press shaping machine uses a food container, plate, dish, or bowl mold to dry and set the wet semi-finished product of the paper mold through the dual effects of heating and pressure to obtain a dry product with high surface density, good strength and high smoothness.

Sugarcane bagasse products

sugarcane bagasse products making machine is apt for manufacturing pulp molded tableware, encompassing various items like fast food boxes, dishes, bowls, and more. Additionally, it is well-suited for producing high-quality wet-pressed paper mold products

Bagasse food container making machine raw material

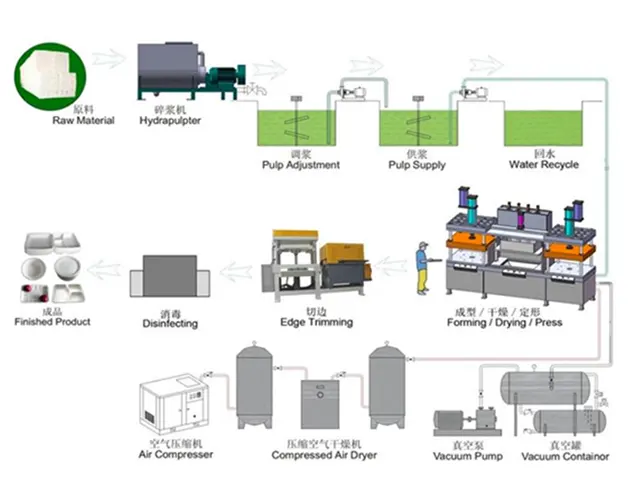

Bagasse food container making machine utilizes virgin pulp sheets made from various sources such as bagasse pulp, bamboo pulp, wood pulp, wheat straw pulp, or other types of pulp. The manufacturing process involves pulp making, forming, hot pressing, trimming, and disinfecting. The final step includes drying in a mold-type thermoforming machine.

Sugarcane bagasse food container machine process

The fully automatic design seamlessly integrates the four key processes: pulping, forming, drying, shaping, edge cutting, sterilizing.

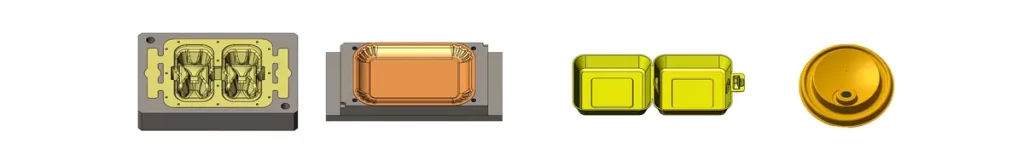

Sugarcane bagasse products making machine moulds

In addition, we have innovatively developed various molding dies tailored for specific applications. These include molds for egg cartons, fruit trays, shoe trays, paper cup covers, disposable dinnerware, meal boxes, and food container pulp molding machines within our comprehensive production line.

Bagasse food container making machine features

Stability of Control System

All systems involved in the paper pulp production process are closely linked with each other. The disposable pulp molding machine systems work automatically as per the operational settings. Therefore, a steady and durable control system is needed to make sure that each process is performed accurately and simultaneously.

Qualification Rate

Qualification rates directly reflect the productivity of the machine and also the working state of the molding machine. To manufacture efficient and up to the mark products, the mold should be clean, perfect in size and shape, and should be robust and sturdy. So you can get good quality degradable molded paper tableware from a paper tableware paper cup eco friendly pulp container making machine.

Program design process for pulp paper food container making machine:

- Technical consultation

- Project evaluation

- Detailed factory design

- Installation and comprehensive testing of the entire production line

- Training programs for engineers and workers

- Long-term provision of spare parts for ongoing support and maintenance.

There are more kinds of food container making machine for your selection.