Fast Food Box Machine|Lunch Box Machine|Disposable Takeaway Food Box Machine

Fast food box machine (paper food container making machine) is specialized forming equipment designed for producing various paper products. It is capable of manufacturing cartons made of cardboard and corrugated paper, including hamburger boxes, square boxes, and food boxes (suitable for take-out).

Paper lunch box making machine features:

- Paper lunch box making machine boasts stable quality, high efficiency, with the highest speed reaching 160 PCS/MIN.

- Versatility: With the same machine, various products of different specifications such as lunch boxes, three-dimensional boxes, hamburger boxes, French fries boxes, and others can be manufactured simply by changing the mold

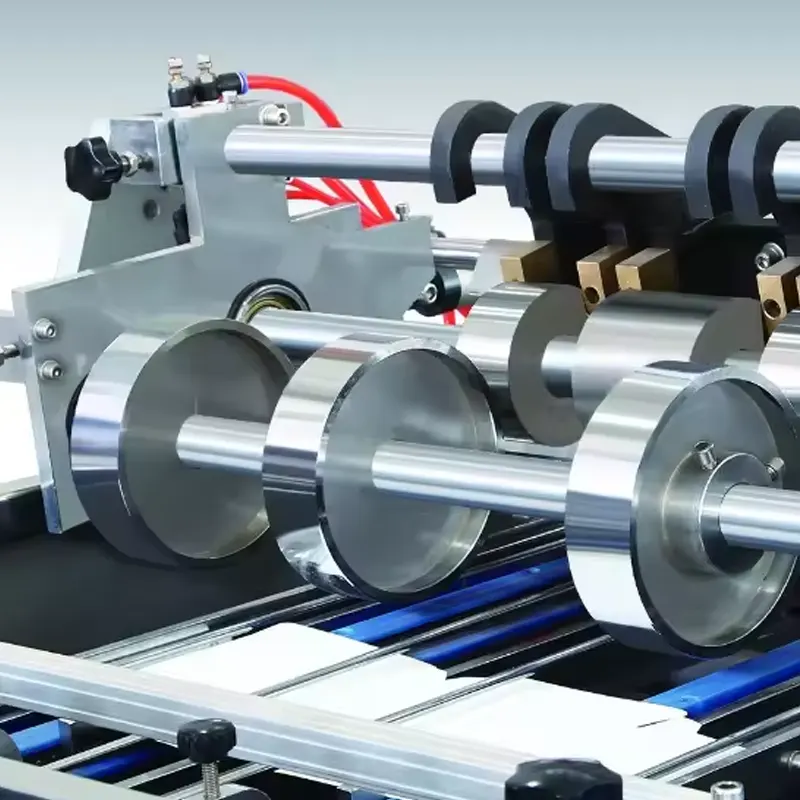

- paper food container making machine utilizes a water-based glue gluing device, ensuring high efficiency and precision

- Water-based glue is a food-grade adhesive that is water-soluble and highly safe.

The process of disposable paper lunch box making machine

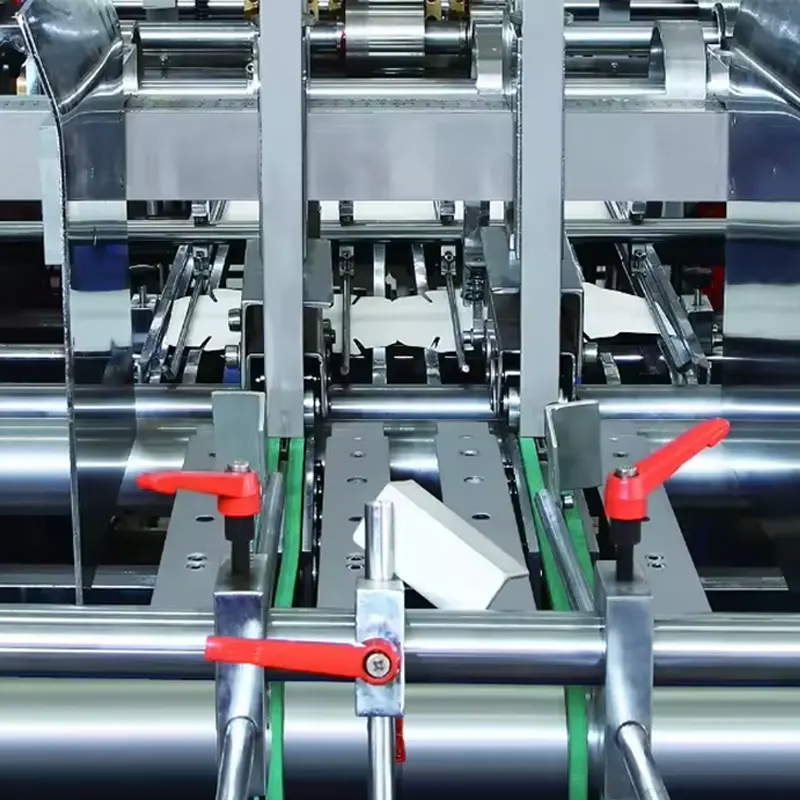

The feeder transports pre-printed and pre-cut cardboard from the paper shelf to the conveyor chains, guiding it to the shaping mold. During this process, the cardboard is glued, and you have the flexibility to adjust the gluing position. The amount of glue applied can be measured continuously without interrupting the operation. Once glued, the cardboard is conveyed for shaping and collection. disposable paper lunch box making machine automatically calculates the predetermined quantity and marks it without halting production.

The feeder transports pre-printed and pre-cut cardboard from the paper shelf to the conveyor chains, guiding it to the shaping mold. During this process, the cardboard is glued, and you have the flexibility to adjust the gluing position. The amount of glue applied can be measured continuously without interrupting the operation. Once glued, the cardboard is conveyed for shaping and collection. disposable paper lunch box making machine automatically calculates the predetermined quantity and marks it without halting production.

The parameters of lunch box making machine

| Raw Material | 200-600g/m² cardboard |

| Productivity | 60-200pcs/min |

| Box Length | 100-450mm |

| Box Width | 100-600mm |

| Box Height | 15-200mm |

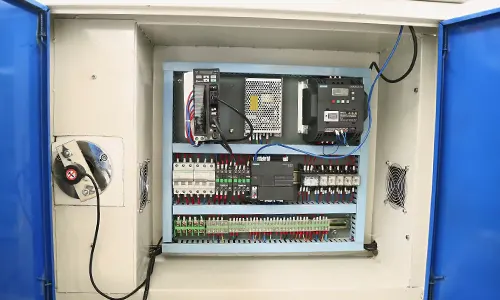

| Power Source | 380V 50Hz |

| Total Power | 5.5Kw |

| Dimensions | 3600×1350×1500mm |

| Weight | 1800kg |