PE Air Bubble Film Machinery | 2/3/5/7-Layer Automatic Bubble Wrap Machines for Sale | China Manufacturers & Best Prices

Bubble Wrap Film Machine Description:

Air bubble sheet extruder machine (also named bubble wrap machine) is designed to produce air bubble films, which are widely used in packaging for shock absorption, cushioning, and insulation. Bubble wrap machines transform raw plastic materials into flexible sheets with evenly distributed air pockets, offering protection for fragile items during transportation and storage.

Air bubble film is a kind of packing material that has been widely used at present.it not only has a good cushioning effect. Shock resistance and heat-sealing performance. But also has such advantages as good corrosion resistance and transparency, etc. So it has been widely used for packing household wares, postal parcels, precision instruments, bicycles, polyurethane furniture, etc.

Bubble Film Raw Materials And Working Principle

- Material Processing: Air bubble film extruder machine starts by melting raw materials such as LDPE (Low-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), or recycled plastics through an extruder.The molten plastic is then forced through a T-die to form a thin, continuous film. To enhance the aesthetic appeal of bubble film, color masterbatch can be added to the raw materials to change its color.

| Item | Single-Layer | Multi-Layer (2-7 layers) |

| Application | Basic machines for standard bubble films | Enable co-extrusion with materials like aluminum foil or anti-static layers for enhanced performance |

| Output | 80–300 kg/h (varies by model) | |

| Film Width | 600–3,000 mm | |

| Bubble Size | 6–32 mm (customizable) | |

| Energy Consumption | 108.5–178.5 kW (depending on capacity) | |

| Voltage | 380V/3-phase | |

Air bubble films Application

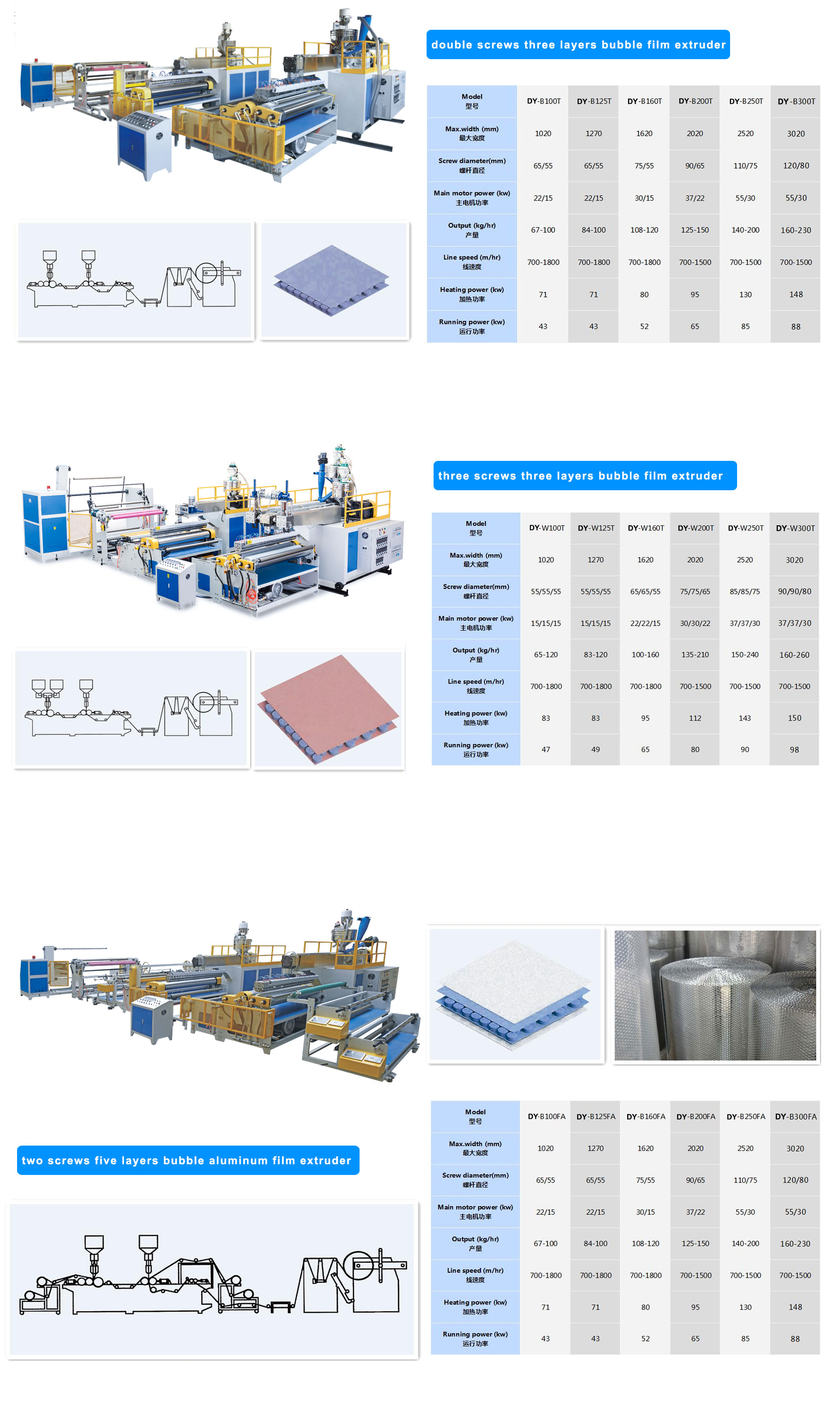

Bubble Film Machinery Parameter And Type

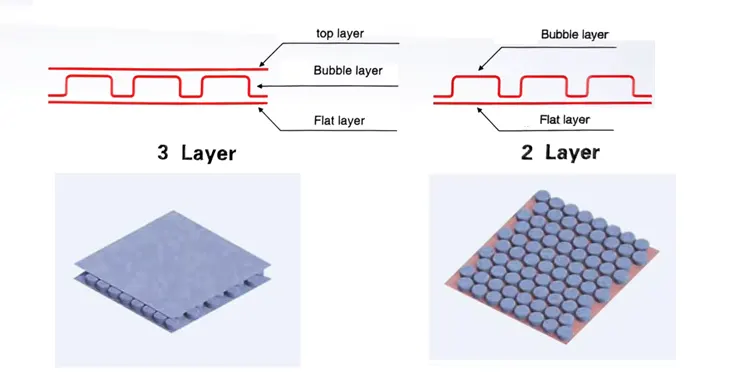

Polyethylene bubble film (also called polyethylene bubble film).which is divided into two kinds: ordinary polyethylene air-bubble film and composite polyethylene air-bubble film. The polyethylene bubble film machine can produce multi-layers(or single layers).

CONTACT US:

Explore our 3/5/7 – layer PE air bubble film machines—automatic, durable, and customizable. Competitive prices from leading manufacturers. Get your free quote today!